| Vocabulary Term & Descriptions | |

| alignment | In a belt drive system, the arrangement of pulleys or the shafts on which the pulleys are mounted. Proper alignment is necessary for effective power transmission. |

| asperities | Microscopic peaks found on all surfaces. Contact between asperities on different surfaces causes friction. |

| backing | The material that surrounds the tensile member of a synchronous belt. The backing is generally made of neoprene. |

| backlash | The distance that a synchronous belt will move while meshing with a pulley that is not moving. |

| bearing | A friction-reducing device that allows one moving part to glide past another moving part. |

| belt | A band of flexible material that is looped around two or more fixed pulleys to transmit motion. Belts are made of various materials and come in different types, such as flat belts, round belts, and V-belts. |

| belt drive system | A mechanical system consisting of a flexible belt and at least two fixed pulleys that is used to transmit motion. Belt drive systems are low maintenance and do not require lubrication. |

| belt joint | A device used to join a flat belt into an endless loop. Common types of belt joints include lacing and hooks. |

| belt span | The distance on a belt from the center of the shaft on one pulley to the center of the shaft on the other pulley. |

| belt tension tester | A device used to check the tension of a belt drive system. |

| centimeters per minute | A metric unit used to measure the speed of a belt drive. Centimeters per minute is abbreviated as cpm. |

| chain drive system | A system consisting of a chain and sprockets that is used to transmit motion. |

| classical V-belt | A type of V-belt designed for heavy-duty applications, which can be used together with other belts to transmit power. Classical V-belts are also known as multiple V-belts. |

| cogged V-belt | A type of V-belt that is notched on its underside to allow the belt to flex more easily. Certain types of cogged V-belts offer quieter operation than other types of V-belts. |

| compression section | The part of a V-belt that supports the tension section. The compression section is generally made of rubber or rubberized fabric. |

| conveyor belt | A belt used in industry to transport materials over a distance. |

| creep | A condition that occurs in flat belt drives that causes the belt to move forward slightly on the driving pulley, which causes the driven pulley to rotate at a slower speed. |

| cross-section | The section width of a V-belt that is used to indicate the size of the belt. V-belt cross-sections are measured in height and width. |

| Created By : harish adhikari On 2013-01-13 | |

| What is v-belt |

| A belt is a loop of flexible material used to link two or more rotating shafts mechanically. Belts may be used as a source of motion, to transmit power efficiently, or to track relative movement. Belts are looped over pulleys. In a two pulley system, the belt can either drive the pulleys in the same direction, or the belt may be crossed, so that the direction of the shafts is opposite. As a source of motion, a conveyor belt is one application where the belt is adapted to continuously carry a load between two points. |

| Created By : harish adhikari On 2012-11-17 |

| D & D Power Drive belt |

| D&D is truly an international company with a long history of manufacturing v-belts. The company started manufacturing belts 40 years ago. Today it is a truly international company with manufacturing facilities and offices in different parts of the world. Our objective is to be the world leader in providing the best low cost quality belt in the power transmission market. |

| Created By : harish adhikari On 2012-11-17 |

| RIGHT TIME TO REPLACE THE V-BELT |

|

Though it is pretty difficult to predict life of a V-Belt like many other products. Since V-Belt life depends on three main factors. Manufacturing Factors Installations Factors and User Factors Manufacturing Process involves use of Quality raw material, Formulation and Process Control. Installation Factors involves Alignment, Tensioning. And User Factors involve the issue at the time of actual running times like temperature, dust, and presence of other external element. And if we can provide the best of above all, the life of and endless V-Belts can be endless too. One way to find out is to examine the belt. If a V-belt is full of tiny cracks, frayed, has pieces of rubber missing, is peeling or otherwise damaged, it needs to be replaced -- NOW. Also, if a belt is oil soaked or "glazed" (hard shiny appearance on the sides of the belt) it also needs to be replaced. Either of these two conditions can cause the belt to run hot, which can weaken it and increase the danger of it breaking. Unfortunately, a visual inspection alone isn't a sure-fire method of determining the true condition of a belt because internal wear that you can't see is just as important as external wear that you can see. All belts are reinforced with cords. The cords are what give the belt its strength and keep it from stretching or breaking. But as a belt ages, the constant flexing, heat and strain weakens the cords. Eventually the cords reach a point where failure can happen suddenly and unexpectedly. The belt may still look good as new on the outside, but be on the verge of snapping internally because the cords have lost their strength. So the other factors that need to be considered when judging the condition of a V-belt include the belt's mileage and age. A V-belt that's more than three or four years old and has more than 40,000 or 50,000 miles on it may be a belt that is nearing the end of its useful service life. For this reason, you might be well advised to replace a high mileage belt even if it still looks okay |

| Created By : harish adhikari On 2013-01-01 |

| MACHINE USED IN V-BELT MANUFACTURING | |

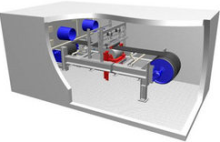

| Comparative Test Rigs are widely used for testing the durability of production belts. These have proven more efficient as compared to others for testing and are available with one side motor and other side generator torque load, which is increased by generator. Furthermore, these are available in different models along with various specifications to fulfil the requirements | |

Features:

|

|

| V- Belt Process Machinery is used in various industries. These machines are widely appreciated due to their longer functional life, easy installation, less maintenance, sturdy construction and reliability. These machines can be customized as per the specifications required. | |

|

Profile Base Calendars that are widely used in several industries. Specifications:- Size:

|

|

|

Jacketing Machines are specially fabricated for tight jacketing of fabric on application base. Using ideal rollers and pulley system, these machines generate the pressure at the top, side and bottom. Eliminating and throwing in line of machine, these machines are provided for rubberized fabric bobbin. In these machines, all systems are drawn by motorized system.

Production capacity :- 15 to 20 mtr. jacketing per minute |

|

| Created By : harish adhikari On 2013-01-01 | |